Choosing the right CNC machine shop is a big decision. You’re not just hiring someone to make parts or products—you’re selecting a partner who can help ensure your project’s success. From advanced technology to outstanding customer service, the best machine shops excel in multiple areas. Let’s take a closer look at what sets them apart.

Looking for a machine shop near you? Let EVS Metal help! Request a quote online, or give us a call at 1-888-9EVS-MET for more information

1. All-in-One Manufacturing Services

The best machine shops offer all of the major metal fabrication and manufacturing solutions under one roof. They handle everything from CNC machining and laser cutting to in-house automated powder coating and robotic forming, eliminating the need to coordinate between multiple vendors, saving time and reducing the risk of miscommunication or inconsistencies.

For example, a project requiring custom enclosures may involve cutting, forming, welding, and finishing. A shop offering all these services in-house can ensure seamless transitions between stages and maintain tight quality control. Additionally, shops with integrated services often have faster lead times since they don’t rely on outsourcing.

2. Cutting-Edge CNC Technology

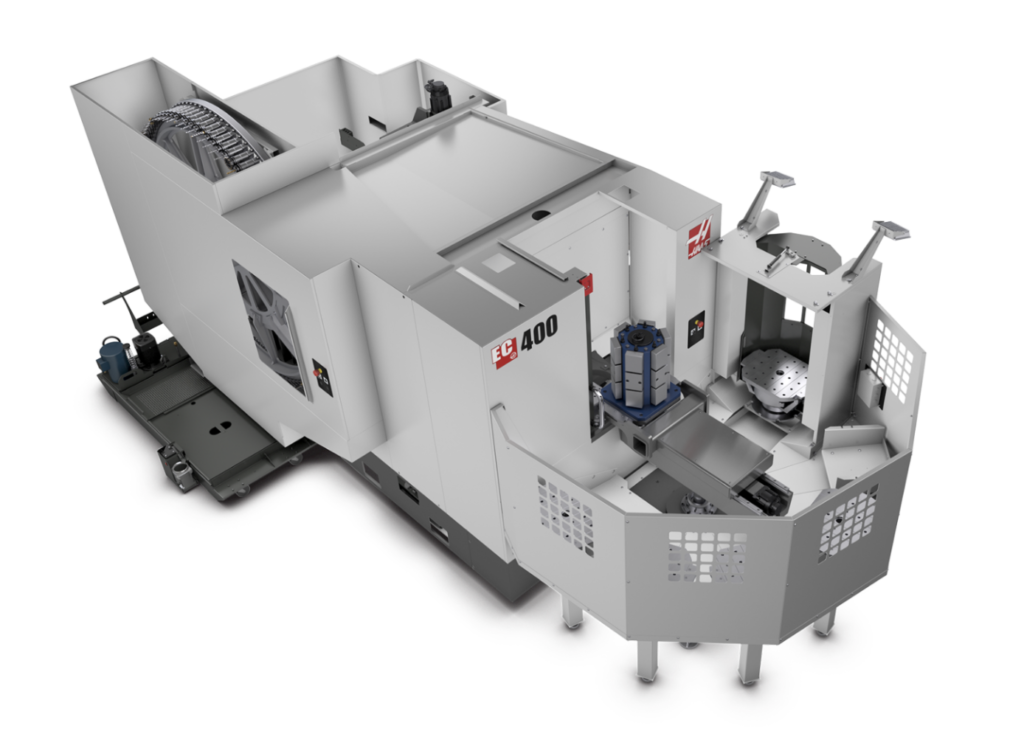

Technology is the backbone of any quality machine shop. Modern CNC (Computer Numerical Control) machines enable precision that was unthinkable a few decades ago. These machines can handle complex geometries, tight tolerances, and high-volume production runs while maintaining consistency across every part.

Shops using 5-axis CNC machines have a significant edge—they can create intricate parts with fewer setups, reducing production time and costs. Offering different machining station orientations, such as vertical vs. horizontal, can also increase the options for better outcomes. Additionally, advanced software like CAD/CAM integration allows for digital simulations before production, catching potential design issues early in the process.

3. Customer Service That Actually Serves You

Strong customer service is about more than just answering emails quickly (although that’s important, too). It’s about clear communication, proactive updates, and a willingness to collaborate. The best machine shops assign a dedicated project manager to oversee your job, acting as a single point of contact who knows your project inside and out.

A good shop will also offer support during the design and engineering phase, suggesting tweaks to improve manufacturability or reduce costs. They’ll keep you informed about progress and any potential delays, so there are no surprises.

4. Versatility is a Must

A quality machine shop can handle a wide variety of materials and machining techniques. This versatility is critical because it allows them to tackle unique challenges across different industries.

For example, some projects may require lightweight materials like aluminum, while others need the durability of stainless steel or the heat resistance of titanium alloys. A versatile shop has the equipment and expertise to work with all of these.

Services should also include everything from milling and turning to grinding and drilling, ensuring they can produce parts for aerospace, medical devices, automotive, and more.

5. Location, Location, Location(s)

While many machine shops can ship products worldwide, proximity can still make a big difference. A shop located near your operations can significantly reduce transportation costs and lead times, especially for large or heavy components.

For companies with ongoing projects, a nearby machine shop makes it easier to visit the facility, review progress, and ensure everything is on track. This accessibility also allows for quick adjustments if specifications change mid-project. That’s why EVS Metal operates four facilities across the U.S., including two — Pennsylvania and Texas — with dedicated CNC machine shops, meant to conveniently serve our customers in both the North- and Southeast.

6. Quality Assurance You Can Count On

When it comes to manufacturing, QA and QC aren’t just important—they are essential. A reputable machine shop follows strict quality assurance and quality control processes to ensure every part meets your exact specifications.

Look for certifications like ISO 9001:2015, which demonstrates a commitment to maintaining high-quality standards. Advanced inspection tools like CMMs (Coordinate Measuring Machines) and laser scanners help verify dimensions with extreme accuracy. Regular audits and traceability systems ensure that every step of production is documented and meets regulatory requirements.

7. Fair Pricing with No Surprises

A trustworthy machine shop provides clear, itemized quotes that break down costs for materials, labor, and additional services. Transparency is key—there shouldn’t be any hidden fees popping up after the fact.

The best shops also offer value beyond pricing. They might suggest ways to optimize your design for cost savings or to reduce material waste. While the cheapest option isn’t always the best, competitive pricing combined with expertise and honesty can create long-term savings.

8. Experience Matters

Experience goes hand in hand with reliability. A machine shop with years of experience in your industry is better equipped to anticipate challenges and deliver high-quality results.

For instance, a shop specializing in those for food service understands the need for lightweight materials and finishes that eliminate porosity, while one focused on medical devices knows how to comply with stringent FDA regulations. Reviewing case studies, customer testimonials, and portfolios can help you gauge whether a shop’s expertise aligns with your project’s needs.

After more than 30 years in the metal fab industry, EVS Metal has the experience across most industries to ensure that your parts and products meet or exceed most any standard.

The Bottom Line

A quality machine shop like EVS Metal isn’t just a vendor—it’s a partner in your success. Whether you need complex parts, quick turnaround times, or expert advice, the right shop will have the tools, team, and technology to deliver. By focusing on these eight features, you can ensure that your project is in the best possible hands.

Choosing a machine shop is about more than just getting parts made—it’s about finding a resource you can trust to bring your ideas to life, efficiently and flawlessly. With the right shop, you’ll save time, reduce stress, and get the results you need every time.

Looking for the best CNC machine shop? Look no further than EVS Metal. Request a quote online or give us a call at 1-888-9EVSMET to learn more about how we can serve your aluminum, steel and stainless steel machining needs.

Article revised 11.26.24