PRECISION SHEET METAL FABRICATION

When it comes to metal fab, we’re the experts.

From lights-out robotic bending and turret punch pressing to state-of-the-art laser cutting, EVS can do it all.

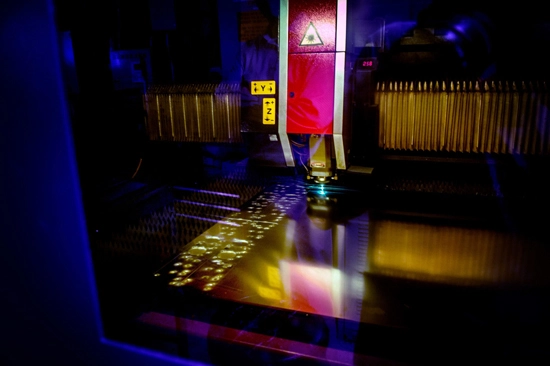

Turret Punching & Laser Cutting

The foundation of our precision sheet metal fabrication offerings begins with laser cutting and turret punch pressing. The speed and accuracy of our CNC punch presses and cutting lasers is unparalleled. These superior technologies give us a distinct advantage in terms of part costs, all while consistently delivering top-tier quality that exceeds industry standards. With a fleet of 17 large-capacity machines, we have the capability to run production seamlessly, even lights-out and unattended, ensuring we meet and exceed your project requirements. And, our exceptional operator skill level is guaranteed by a comprehensive, on-site training program, ensuring your projects are in the very best hands.

Metal Polishing, Graining & Deburring

To provide scratch- and burr-free parts, we utilize state-of-the-art Timesavers® graining/deburring machines and an extensive array of tumbling and grinding equipment. From grained finishes to the brilliance of #8 mirror stainless, our highly-skilled techs can handle every surface metal finishing need for metal parts.

Metal Forming & Bending

In our metal forming and bending department, we’ve harnessed the power of the latest fabrication technology, including ultra-modern automated bending robots. Our choice of European-style press brake tooling enhances precision, extends tool life, and streamlines setup time, giving us an edge in delivering the highest quality. With 27 press brakes seamlessly networked to store programs and expedite repeat job setups, your projects are handled with efficiency and accuracy. We’ve even integrated Amada® BendCAD software to program brakes offline, further reducing downtime and lead times.

Hardware Insertion

Our hardware insertion capabilities feature massive capacity, including 33 Haeger® insertion presses, most equipped with automated feeds to maximize efficiency.

OTHER EVS CAPABILITIES

METAL FABRICATION

CNC MACHINING

WELDING

FINISHING

ASSEMBLY/INTEGRATION

Already know

what you're looking for?

Let’s get a sheet metal fabrication quote started.