Metal Fabrication Services

DESIGN & ENGINEERING

At EVS Metal, we take pride in offering design for manufacturability and engineering assistance for our valued clients’ metal fabrication needs. Once provided with specific part requirements, we are able to help develop an assembly concept, then generate a full set of blueprints and assembly drawings. All designs are created based on a set of pre-specified sheet metal design considerations and including tolerances that ensure products are fabricated with precision to exact specifications.

Our knowledgeable and courteous engineering staff, who have helped develop hundreds of enclosure designs that address even the most complicated specifications, is available to assist with every aspect of the design process. For existing design work, our engineers leverage their experience in design for manufacturing to help clients identify changes that can reduce cost as well as alleviate issues caused by tolerance stack-up in assemblies.

All CNC machinery on the shop floor is connected directly to our network, allowing for safe, controlled storage and immediate access to all CNC programs. In addition, we use the Mastercam© CAM system to generate programs for our machining centers. At EVS Metal, everything we do is aimed at 100% client satisfaction.

Design for Manufacturing in Metal Fabrication

The EVS Metal Design Center offers design for manufacturing (DFM) assistance when our customers come to us with DFM-specific metal fabrication challenges in product categories including:

- Chassis

- Card cages

- Machined Components

- Weldments of all sizes

- Subassemblies

- Outdoor enclosures

- Thermal management

- Shock and vibration

- UL certified type 1 508A enclosures

- NEMA-rated electrical enclosures

EVS uses the unrivaled SolidWorks© CAD software to perfectly model and unfold newly-designed parts for future fabrication. Solid modeling allows EVS to transfer designs to metal quickly and accurately, as well as identify potential manufacturing problems at the design stage. This means any errors are corrected before parts are fabricated, saving time and money. EVS also maintains seats of Pro-Engineer and can import most CAD models in formats such as IGES or STEP.

EVS utilizes the Amada’s AP100US and Dr.Abe_Blank CAM systems to program our lasers and turret presses swiftly and precisely. Amada’s Dr.Abe_Bend and Dr.Abe_Astro are used for programming our manual and robotic press brakes.

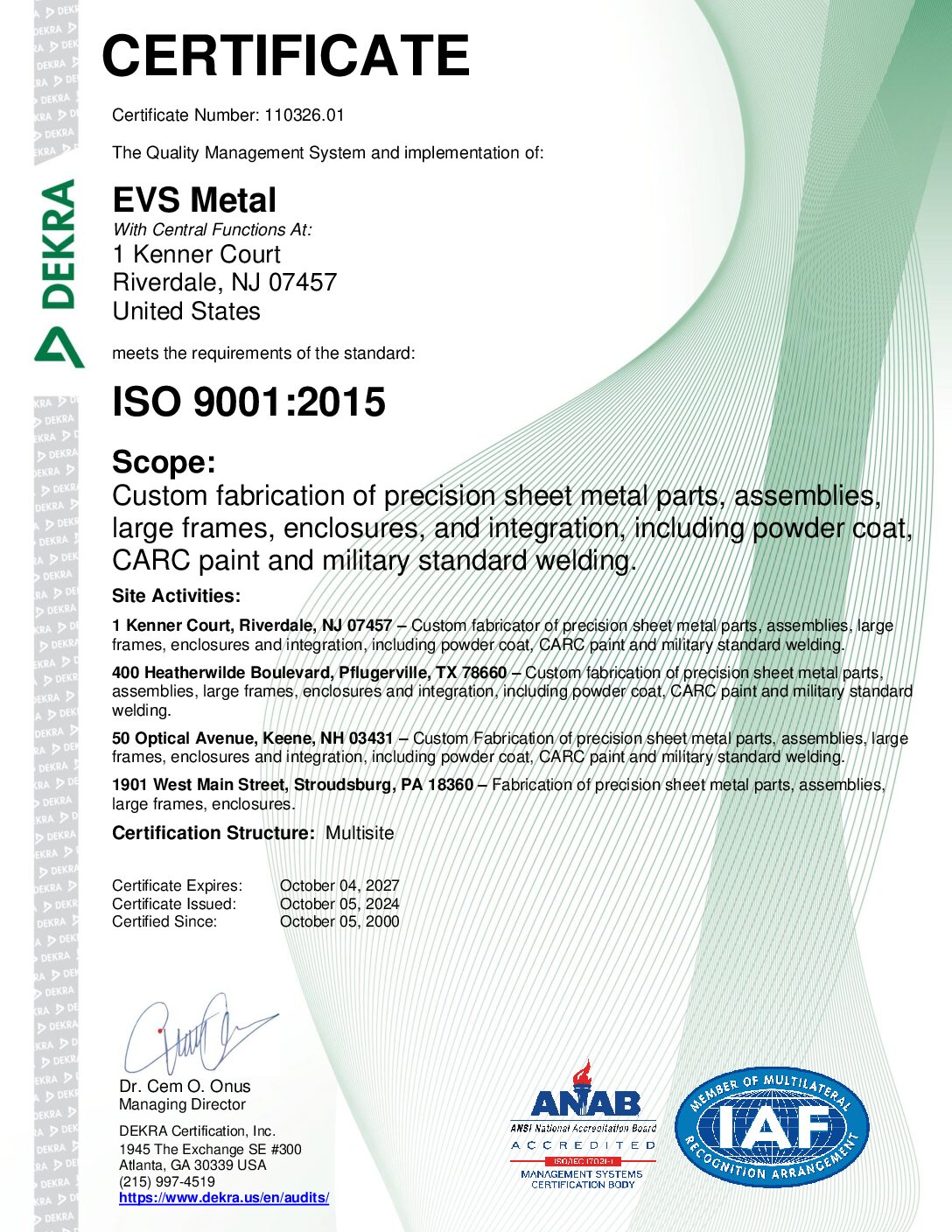

QUALITY

Our corporate quality control system is registered to the ISO 9001:2015 standard. EVS Metal has cultivated a culture that is dedicated to continuous improvement, which enables our company to consistently fabricate and finish metal parts and products of the highest quality. Our computerized quality records provide traceability and accountability. Utilizing Amada’s FabriVision to scan and accurately inspect flat parts along with other advanced technologies has enabled EVS to become a dock-to-stock vendor for many of our clients, which is a testament to the quality and integrity of our products.

LOGISTICS

EVS Metal works with customers throughout the United States and worldwide in Canada, China, Thailand, Europe and Mexico to deliver quality, cost-effective logistics solutions. Our expertise in handling shipments locally and globally ensures product is delivered on time and undamaged.

Delivery by EVS Truck

EVS maintains a fleet of vehicles including a 56′ tractor-trailer, 24′ box trucks and cargo vans to handle delivery of product within a 300-mile radius of our facilities. Delivery by our vehicles and employees allows parts to arrive when our clients need them, and with a minimum of packaging waste. Bus runs are also available to satisfy daily requirements.

Delivery by Common Carrier

EVS Metal maintains excellent relationships with a number of regional and national carriers in order to provide economical shipping options outside of the reach of our trucks. Solutions include both next-day delivery and scheduled delivery of warehoused items.

Overseas Shipments

EVS has many years of experience in shipping product overseas. Our relationships with carriers and experience with damage-resistant packagings ensure our customers’ international shipments arrive safely and on time.

Managed Inventory

With contract orders, EVS Metal can manage client inventory by controlling production to meet the required volume, even when there is fluctuating demand. This can be done through kanban programs or electronic requirement sharing. EVS can download customers’ MRP requirements and adjust both production and the supply chain to minimize inventory exposure. EVS is also proficient at managing consigned inventory on the customer’s premises or in third-party warehouses.

EVS can easily handle the final packaging and shipment to clients’ end customers via electronic communication and with minimal client involvement. By sharing projections we manage the supply of parts and work to replenish an agreed-upon inventory level.

Enterprise Resource Planning (ERP)

In order to accurately monitor and control inventory, EVS Metal utilizes an ERP (enterprise resource planning) system by MIE Solutions — MIE Trak Pro software. For more than two decades, MIETrack has provided our precision sheet metal fabrication and manufacturing business with an excellent “all-in-one” solution. Our ERP software helps streamline the entire manufacturing business process from RFQ through product delivery. It also offers a window into any area of the company by utilizing real-time data collection. This means less manual inputting and tracking, leaving more time for business development and customer engagement, and ultimately results in cost savings for both EVS and our clients.

ITAR Registration

As an end-to-end American sheet metal fabrication, finishing and integration leader, EVS Metal is proud to operate an International Traffic in Arms Regulations (ITAR)-registered manufacturing facility in Pflugerville, Texas, just outside of Austin.

ITAR registration is approved by the U.S. State Department’s Directorate of Defense Trade Controls (DDTC). The U.S. Government requires all of its contracted manufacturers, exporters and brokers of defense articles, services or technical data to be ITAR compliant. Registration allows EVS to submit bids and subsequently operate as a manufacturer of defense articles for the United States Government and its authorized subcontractors.

“As an American company, and experts in our field, we are honored to be able to assist our government in meeting its defense manufacturing needs,” stated Joe Amico, Vice President and co-founder of EVS Metal. “Knowing that with our work we are contributing to something much bigger than ourselves is incredibly rewarding.”

Enacted in 1976 during the Cold War, ITAR is primarily a means to provide the U.S. Government with necessary information on which companies are involved with certain manufacturing and exporting activities. ITAR regulations cover many different aspects of manufacturing, but the most important edict that must be followed is ensuring that all information and material related to U.S. defense and military-related technologies is only shared with U.S. Persons unless otherwise authorized by the Department of State.

MANUFACTURING STANDARDS

Click here to download the list in PDF format.

The following information describes EVS Metal’s manufacturing standards:

In the event that details regarding tolerancing are not provided (for example: when we receive only a solid model or a physical sample, an undimensioned or under-dimensioned print) these tolerances will be applied. EVS Metal may also specify that a quotation is based on these standards at the time of quote when tolerance on a print cannot be met with standard manufacturing methods. While this does not indicate the tightest manufacturing standards & tolerances that EVS can hold, it represents referenced industry standards achievable with our normal manufacturing processes. While the addition of secondary processes such as reaming, machining, hard tooling, etc. may improve the tolerances which can be held, they will impact cost. Any critical tolerances must be indicated as such by the customer upon placement of an order and will be evaluated by our Engineering Department for manufacturability.

Unless we at EVS receive specific instructions to the contrary, all dimensions/tolerances are to be applied before finishing.

Solid Model format by order of preference: Solidworks (.SLDPRT, .SLDASM), Pro-E (.PRT, .ASM), Parasolid, STEP, IGES`

| Locational Dimensions | |

|---|---|

| Description | Tolerance (inches) |

| Edge to Bend across 1 or 2 bends | +/- .010 |

| Edge to Bend across 3 bends | +/- .015 |

| Edge to Edge across no bends |

+/- .005 |

| Edge to Edge across 1 or 2 bends | +/- .010 |

| Edge to Edge across 3 bends | +/- .015 |

| Bend to Bend across 1 or 2 bends | +/- .010 |

| Bend to Bend across 3 bends | +/- .015 |

| Feature to Feature across 4 bends | +/- .020 |

| Feature to Feature across more than 4 bends | +/- .020 +.005 each additional bend |

| Edge to Hole across no bends | +/- .005 |

| Hole to Bend formed off the same plane | +/- .010 |

| Hole to Hole on same plane across 4 bends | +/- .020 |

| Part to Part in welded sheet metal assembly | (see note) |

| Note: due to the inherent differences in welded assemblies, EVS will review customer requirements and establish acceptable standards prior to starting production. |

|

| Description | Tolerance (inches) |

|---|---|

| Hardware Hole Diameter | +.003 / -.000 |

| Hole Diameter | +/- .005 |

| Countersink Major Diameter | +/- .005 |

| Countersink Minor Diameter | +/- .010 |

| Standard Dimensions | |

|---|---|

| Description | Tolerance |

| Angular | +/- 1 degree |

| Fractional | +/- 1/64 |

| Standard For Turret Formed Countersinks to avoid distortion caused by material displacement |

| Metal Fabrication & Manufacturing Quality Tolerance Standards |

| EVS DEFAULT PLATING SPECIFICATIONS | ||

|---|---|---|

| Process | Material or other pertinent factors | Specification nomenclature |

| Clear Zinc | N/A | ASTM B633-98, Class FE/ZN 8, Type III |

| Yellow Zinc | N/A | ASTM B633-98, Class FE/ZN 8, Type II, Yellow Chromate |

| Black Zinc | N/A | ASTM B633-98, Class FE/ZN 8, Type II, Black Chromate |

| Clear Iridite | N/A | MIL-C-5541E, Class 1A, Clear |

| Yellow Iridite | N/A | MIL-C-5541E, Class 1A |

| Electrodeposited Nickel | COPPER | QQ-N-290A, Class 1, Grade D |

| Electrodeposited Nickel | STEEL | QQ-N-290A, Class 1, Grade C |

| Electroless Nickel | ALUMINUM | MIL-C-26074E, Class 1, Grade A |

| Electroless Nickel | COPPER | MIL-C-26074E, Class 1, Grade B |

| Electroless Nickel | STEEL | MIL-C-26074E, Class 1, Grade C |

| Anodize – Clear | N/A | MIL-A-8625F, Type 2, Class 1 |

| Anodize – Black | N/A | MIL-A-8625F, Type II, Class 2, Black |

| Anodize – Gold | N/A | MIL-A-8625F, Type II, Class 2, Gold |

| Anodize – Grey | N/A | MIL-A-8625F, Type II, Class 2, Grey |

| Tin Plate | BRIGHT DIP must be specified if required | ASTM-B545-97, Class A |

CERTIFIED ENCLOSURES

UL-Certified Type 1 508A Enclosures

EVS Metal’s NJ facility is authorized to design and build UL-Certified Type 1 508A Enclosures. View the industrial standards here.

This capability allows our clients to authorize EVS Metal to custom fabricate new enclosures that are UL certified. Rather than being forced to choose from pre-fabricated, off-the-shelf enclosures to ensure UL certification, they may instead collaborate with our engineering team to design the exact size and configuration required without being constrained by what is currently in stock from companies with certified product lines.

Additional EVS Metal Certifications

WHITE PAPERS

White Paper: Trends In Metal Fabrication For 2017 And Beyond

The metal fabrication industry may not change as rapidly as others, but never the less, change is definitely still a major consideration for those of us in the manufacturing sector. We simply must be ready to handle whatever the future throws at us. It is with that in mind that we at EVS Metal decided to take a closer look at the metal fabrication trends that are affecting the fabrication market now and will continue to make an impact over the next decade. (Read more...)White Paper: Enterprise Resource Planning

ERP stands for Enterprise Resource Planning. It’s a term that is used as a catch-all for a variety of different business tasks in manufacturing settings, including: • Quoting/estimating • Work orders • Purchasing • MRP (Manufacturing Requirements Planning) • Stock Control • Scheduling • Reporting • Shop floor data capture • Accounting Most ERP software has the ability to do all of the above, but not every company chooses to use their ERP to handle all of the listed tasks. (Read more...)White Paper: Industry 4.0

Many may have heard of Industry 4.0, but it wasn’t until recently that the “fourth industrial revolution” began to take hold in any practical sense. Now that it is starting to gain traction, more and more questions are starting to arise about what it means for manufacturing in terms of real-world implications. (Read more...)White Paper: Total Landed Cost

In terms of the supply chain, businesses need to take into consideration many different factors, especially regarding how each of these variables affects their bottom line. However, with so many elements at play, companies often fail to recognize that one of the biggest contributors to projects going over budget can be seen well in advance: Total Landed Cost (TLC). Download our white paper now to learn why accurately calculating TLC can mean the difference between true profit and sizable loss. (Read more...)