Updated: June 9, 2022

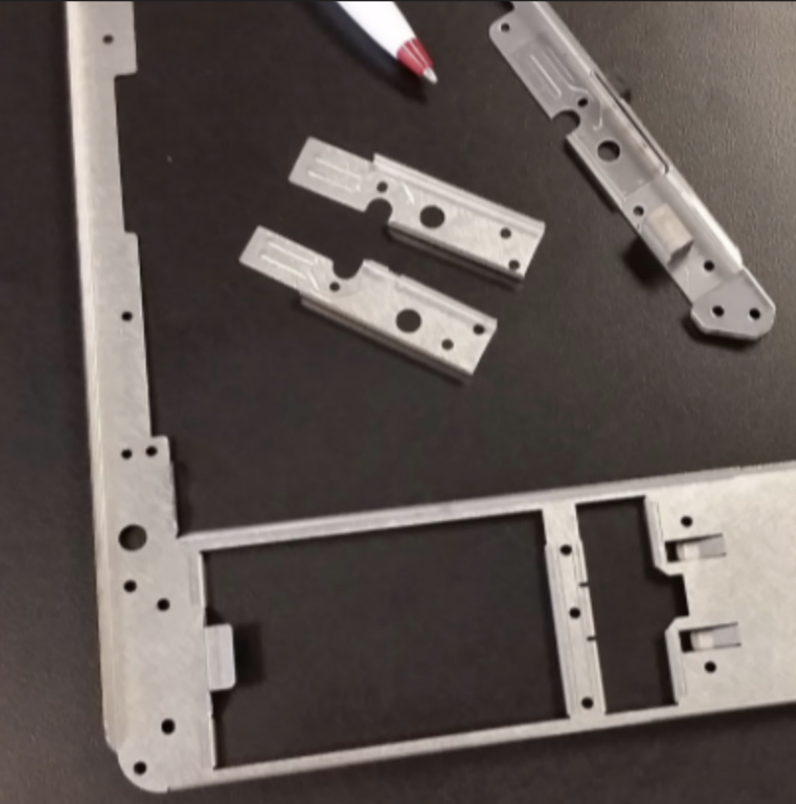

EVS Metal fabricates a wide range of sheet metal parts, including brackets, frames and fixtures for many different industries. After more than 25 years, it’s become clear that there are some definite “dos” and “don’ts” when it comes to designing sheet metal parts for fabrication, many of which can directly affect an item’s cost. The following features a selection of our “top tips” for getting the most out of a sheet metal part design before it becomes a fabricated reality.

Use Uniform Wall Thickness

This may sound basic, but it is not all that unusual to receive a design that calls for more than one wall thickness. While it’s not impossible to fabricate parts in this manner, it will absolutely add cost to the project that can usually be avoided via improvements in the design.

Keep the Metal in Mind

All metals have different properties, which means each must be handled differently during the fabrication process. Some metals are more expensive than others to work with because they can be more difficult to weld or cut. A good example is aluminum, a popular metal that can be used for many applications because of its relative lightness. However, aluminum is generally more difficult to weld than, say, stainless steel. Therefore, if it’s possible to use stainless steel for a part that will need to be welded, that may well be the better choice. Conversely, stainless steel is often more expensive than aluminum overall, so if a part doesn’t require stainless, it can help reduce the cost of the part if aluminum is used instead.

Use Realistic Tolerances

EVS has the ability to fabricate metal parts within extremely tight tolerances. However, that doesn’t mean that every single part can be designed to those standards. Realistic tolerances vary depending on the metal fabrication process being used to manufacture the part. For instance, +/- 0.003” is a more reasonable tolerance for a punched hole diameter. And for bending, because metal bounces back (slightly) after the bend is made, +/- 1° is considered realistic. Too-tight tolerances also add cost to projects that could otherwise be avoided, so always be as generous as possible when considering this aspect of metal part design.

Consistency Cuts Costs

It is almost always less expensive to fabricate parts that keep consistency front of mind within the design. For instance, ensure that required bends are all oriented in the same direction; maintain standard measurements and sizes across the design for holes, notches, and tabs, and be sure that the design can be carried out with standard fabrication tools and equipment.

Choose a Metal Fabricator with Experience

An experienced fabricator, like EVS, will be able to analyze a design for opportunities to create efficiencies that can save money and time. Getting them involved early, during the design and engineering process, often means fewer fabrication headaches down the road.

EVS Metal: Experts in Metal Parts Fabrication

EVS Metal is a leading American commercial sheet metal fabricator and manufacturer using state-of-the-art equipment, including CNC machining centers, turret punch presses and press brakes, to manufacture metal parts with precision and accuracy. The company also offers exceptional assembly and integration services for items large and small. Four convenient metal fabrication facilities are available across the U.S. in New York, Texas, New Hampshire, and Pennsylvania. Contact EVS online today to submit an RFP for a metal parts project, or call 1-888-9EVSMET to speak with a sales representative.