EVS Metal, a leader in precision sheet metal fabrication, commemorates its 30th anniversary. Since its inception in 1994, the company has evolved into a top-tier American metal fabrication enterprise, boasting locations in New Jersey, Texas, Pennsylvania, and New Hampshire.

Riverdale, NJ — EVS Metal, a leading provider of precision sheet metal fabrication solutions, proudly announces its 30th anniversary. Founded in 1994 by Joe Amico and Scott Berkowitz, EVS Metal has grown from a small operation into one of the premier metal fabrication companies in the United States, with facilities in New Jersey, Texas, Pennsylvania, and New Hampshire.

A Journey of Growth and Innovation

In 1994, EVS Metal began its operations with a vision to redefine industry standards through a commitment to quality, customer service, and technological innovation. Starting with a modest, 5000 sq ft sheet metal fabrication facility in New Jersey, the company quickly distinguished itself by adopting advanced manufacturing techniques and investing in state-of-the-art equipment.

Facilities Expansions

Over the next three decades, EVS Metal expanded its footprint significantly. In 2001, the company ventured into Pflugerville, Texas, opening a facility with a dedicated CNC machining shop. This was followed by the expansion into Keene, New Hampshire in 2008, further broadening its capabilities and geographic reach. In 2012, EVS opened its first facility in Pennsylvania, before moving to its current Stroudsburg location, just across town from the original, in 2022.

Technological Investments

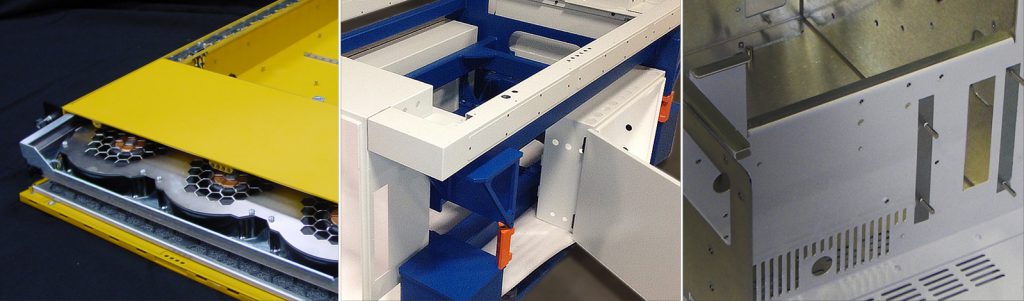

EVS Metal’s 30 year journey has been marked by a relentless pursuit of excellence, not just in the quality of its products but also in its manufacturing processes. Central to this pursuit is the company’s strategic investment in the latest manufacturing technology. From in-house powder coating lines to advanced CNC machine shops and comprehensive automation strategies, EVS Metal has distinguished itself as one of the most respected metal fabricators in the industry. These investments not only streamline operations and improve efficiency but also reinforce EVS Metal’s commitment to delivering superior, durable products to a wide range of industries.

In-House Automated Powder Coating Lines

EVS Metal’s strategic decision to integrate in-house automated powder coating lines across all four of its facilities underscores a deep commitment to delivering products that stand the test of time. This significant technological advancement sets EVS Metal apart from many in the metal fabrication industry, offering a clear competitive edge.

Automated powder coating lines enable a more efficient, consistent, and high-quality application of powder coating compared to manual processes. This automation ensures that each product receives a uniform coat, resulting in finishes that are not only visually more appealing but also more resistant to chipping, scratching, and fading over time. The ability to control the thickness and texture of the coating with precision also means that products are better protected against corrosion, enhancing their durability and longevity, ultimately delivering a higher-quality product.

Advanced CNC Machining Shops

EVS Metal’s advanced CNC machining shops are equipped with the latest in computer numerical control (CNC) technology, allowing for the automation of machine tools with incredible precision based on programmed instructions. This capacity for high-precision machining enables EVS Metal to produce complex parts that meet exact specifications, which is essential for industries where even the slightest deviation can have significant consequences, such as transportation, medical devices, and defense.

The investment in these state-of-the-art CNC machining centers is a reflection of the company’s forward-thinking philosophy. By continuously updating their technology and processes, EVS ensures that they can offer the most efficient and precise machining capabilities available. This not only enhances production capabilities but also reduces turnaround times, providing clients with faster delivery of their custom components without compromising on quality.

Automation

EVS Metal has significantly boosted its operational efficiency and precision through strategic investments in automation, including robotic bending stations, robotic welding cells, and automatic tool changers. These technologies have revolutionized metal fabrication by ensuring uniformity, enhancing quality, and minimizing manual intervention in repetitive tasks.

The adoption of automated technologies has streamlined production and enabled the company’s skilled operators to focus on tackling more complex fabrication tasks, improving product quality as a result. This emphasis on automation highlights their dedication to industry leadership in both efficiency and innovation. Utilizing these technological advancements, EVS has boosted its production capabilities, ensuring it can continue providing high-quality, efficient solutions that meet the ever-changing needs of its clients, reaffirming its position as a leader in the metal fabrication industry.

Fabrication for Diverse Industries

EVS Metal’s expertise in sheet metal fabrication spans a wide array of industries, establishing it as a key partner for businesses across various sectors. The company boasts extensive experience in many sectors, including creating specialized components for the technology and computing, telecommunications and medical and healthcare industries.

EVS Metal’s broad industry knowledge enables the company to meet the specific challenges and needs of each sector with customized fabrication solutions. In the technology realm, the company manufactures critical components for semiconductors and data warehouses, essential for the everyday products we rely on, ensuring durability and precision. For the telecommunications industry, EVS provides components that bolster infrastructure, offering the reliability needed to maintain global connectivity. The medical and healthcare sector relies on the company for the production of highly precise components, meeting strict standards crucial for the functionality of medical devices and equipment. This comprehensive approach not only showcases EVS Metal’s versatility in metal fabrication but also their commitment to supporting the core functions of diverse industries.

Looking Ahead

“We are incredibly proud of what we have accomplished in the last 30 years,” said Joe Amico, Vice President and Co-Founder of EVS Metal. “This anniversary is a testament to the hard work of our team and the trust our customers place in us. As we look to the future, we are excited about the opportunities to further innovate and grow, while continuing to serve our clients with the highest standards of quality and service.”

Scott Berkowitz, President and Co-Founder of EVS Metal, added, “Reflecting on the past 30 years, it’s clear that our commitment to embracing new technologies and processes has been key to our success. We’re not just in the business of metal fabrication; we’re in the business of solving problems and adding value for our customers. Looking ahead, our goal is to continue pushing the boundaries of what’s possible, ensuring that EVS Metal remains at the forefront of the industry.”

The company’s journey from startup to leader in the metal fabrication industry is a story of vision, perseverance, and innovation. As the company celebrates its 30th anniversary, it looks forward to continuing its tradition of excellence and while helping to shape the future of metal fabrication.

About EVS Metal

EVS Metal is an American precision sheet metal fabricator headquartered in Riverdale, New Jersey. Founded in 1994, the company operates four manufacturing facilities across the United States, offering services such as CNC machining, metal fabrication, powder coating, laser cutting and assembly for a wide range of industries. With a commitment to quality and customer service, EVS Metal has established itself as a key player in the sheet metal fabrication industry.