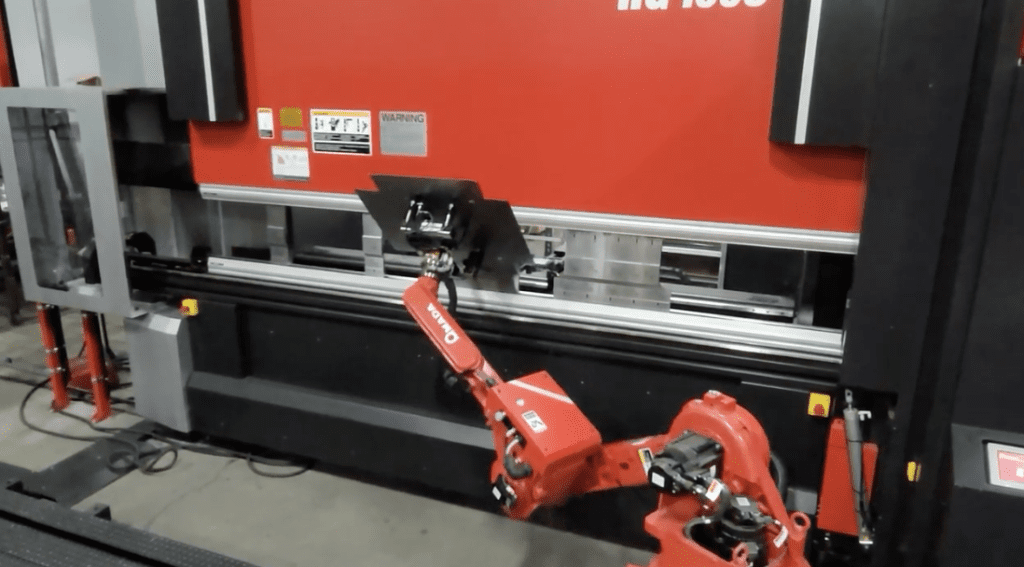

Amada HG 1003 ARs (automated robot) forming medical equipment

Smart automation in precision sheet metal fabrication integrates advanced technologies—robotics, artificial intelligence, machine learning, and IoT sensors—to optimize manufacturing processes, improve quality consistency, and increase production capacity. Unlike traditional fixed automation that repeats predetermined tasks, smart automation systems adapt to changing conditions, learn from data patterns, and make real-time decisions to optimize performance.

The distinction matters for manufacturers evaluating automation investments: traditional automation excels at high-volume, repetitive tasks with minimal variation, while smart automation handles complexity, variability, and optimization across diverse production requirements—the reality of modern sheet metal fabrication environments.

Key Technologies Driving Smart Automation

Modern smart automation systems combine multiple technologies working in concert:

Industrial Robotics with AI Integration – Robotic systems now incorporate vision systems, force sensing, and adaptive path planning. A robotic welding cell doesn’t simply repeat programmed movements—it analyzes weld quality in real-time, adjusts parameters for material variations, and optimizes travel paths for efficiency.

Machine Learning for Process Optimization – CNC machining centers and laser cutting systems collect operational data to identify patterns that improve performance. Machine learning algorithms analyze thousands of cuts to determine optimal feed rates, power settings, and gas pressures for different material conditions, geometries, and quality requirements.

IoT Sensors and Predictive Maintenance – Connected sensors monitor equipment conditions continuously, identifying potential failures before they occur. Predictive maintenance systems analyze vibration patterns, temperature fluctuations, and performance metrics to schedule maintenance during planned downtime rather than responding to unexpected breakdowns.

Digital Twin Technology – Virtual replicas of physical equipment and processes enable simulation, testing, and optimization before implementation. Fabricators can test new part designs, evaluate production sequences, and identify bottlenecks in the digital environment, reducing physical trial-and-error costs.

Real-Time Production Monitoring – Manufacturing execution systems (MES) provide visibility into production status, equipment performance, quality metrics, and material flow across the facility. Real-time data enables faster decision-making and responsive adjustments to changing priorities.

Strategic Applications in Sheet Metal Fabrication

Strategic Applications in Sheet Metal Fabrication

Smart automation delivers measurable value across multiple fabrication operations:

Robotic Press Brake Operation: Modern robotic press brake systems combine force sensing, adaptive bending algorithms, and real-time angle measurement. The system compensates for material variations, springback characteristics, and tooling wear automatically. Operators focus on part verification and system optimization rather than manual angle adjustment and measurement.

Automated Laser Cutting Optimization: Smart nesting software analyzes part geometries, material utilization, cutting sequences, and machine capabilities to optimize every sheet. The system considers not just material yield but also cutting time, pierce locations, lead-in strategies, and part-specific quality requirements. Integration with inventory management ensures optimal material selection for each production run.

Intelligent Powder Coating Lines: Automated powder coating systems control application parameters, cure temperatures, and line speeds based on part geometry, material composition, and coating specifications. Vision systems inspect coverage quality, identify defects, and trigger rework loops automatically, ensuring consistent finish quality across production volumes.

Robotic Welding with Adaptive Control: Advanced robotic welding cells use seam tracking, arc monitoring, and adaptive fill algorithms to compensate for fit-up variations, material inconsistencies, and environmental conditions. The system maintains weld quality despite real-world manufacturing variability that would challenge manual welding or fixed automation.

Automated Material Handling and Logistics: Smart material handling systems track inventory location, automate part movement between operations, and optimize workflow based on production priorities. Integration with ERP systems enables just-in-time material delivery, reducing work-in-progress inventory and floor space requirements.

Implementation Considerations and ROI Factors

Successful smart automation implementation requires strategic planning beyond technology selection:

Process Standardization Requirements: Smart automation performs best when underlying processes are stable and repeatable. Manufacturers should document and standardize procedures before automation implementation. Automating an inconsistent process simply creates automated inconsistency at higher speed.

Data Infrastructure and Integration: Smart automation systems generate substantial data requiring storage, analysis, and integration across enterprise systems. Manufacturing execution systems, ERP platforms, quality management systems, and equipment controllers must communicate effectively. Data infrastructure investment often equals or exceeds equipment costs.

Workforce Development and Change Management: Automation shifts workforce requirements from manual operation to system monitoring, programming, and optimization. Successful implementation includes training programs, clear role definitions, and change management processes that help employees transition to higher-value activities.

Incremental Implementation Strategy: Most manufacturers achieve better results through phased automation implementation rather than facility-wide transformation. Starting with high-volume, well-defined processes builds organizational capability, demonstrates ROI, and informs subsequent automation decisions.

Total Cost of Ownership Analysis: Smart automation ROI extends beyond labor cost reduction. Consider quality improvement, capacity expansion, reduced scrap and rework, faster changeovers, improved on-time delivery, and competitive positioning when evaluating investments. Many manufacturers find quality and capacity benefits exceed direct labor savings.

Measuring Smart Automation Performance

Effective automation requires clear performance metrics:

Equipment Utilization and OEE: Overall Equipment Effectiveness (OEE) measures availability, performance, and quality. Smart automation systems typically achieve 75-85% OEE compared to 50-65% for manual operations, driven by reduced downtime, faster cycle times, and lower defect rates.

Quality Metrics and First-Pass Yield: Automated processes demonstrate higher consistency and repeatability than manual operations. Track defect rates, rework percentages, and customer quality complaints. First-pass yield improvements of 5-15% are common with well-implemented automation.

Throughput and Capacity Gains: Measure production output per shift, changeover times, and ability to handle rush orders. Smart automation typically increases effective capacity 30-50% in automated operations through faster cycle times, reduced changeovers, and 24/7 operation capability.

Labor Productivity and Skill Utilization: Track output per labor hour and analyze how workforce time allocation changes. Successful automation moves skilled workers from repetitive tasks to higher-value activities: programming, process optimization, quality analysis, and customer support.

Return on Investment Timeline: Most smart automation investments in sheet metal fabrication show positive ROI within 18-36 months, depending on production volumes, labor rates, and process complexity. Consider both tangible savings (labor, scrap reduction, capacity) and intangible benefits (quality improvement, competitive positioning, recruitment advantages).

The Human Element in Smart Automation

Despite technological advancement, human expertise remains central to successful automation:

Programming and Process Optimization: Automated systems require skilled programmers who understand both fabrication processes and system capabilities. Optimization—finding the fastest, most efficient, highest-quality production method—remains fundamentally a human problem-solving activity supported by automation tools.

Quality Oversight and Problem Resolution: Automated quality inspection identifies issues, but skilled workers interpret patterns, identify root causes, and implement corrective actions. Human judgment determines when process adjustments, tooling changes, or design modifications are needed.

Continuous Improvement and Innovation: Smart automation generates data revealing improvement opportunities, but humans must interpret insights, prioritize initiatives, and implement changes. The most successful automated facilities maintain strong continuous improvement cultures where workforce expertise drives ongoing optimization.

Customer Collaboration and Engineering Support: Automation capabilities enable faster response to customer requirements, but human expertise translates customer needs into manufacturable designs, recommends materials and processes, and solves technical challenges. Automation amplifies human capability rather than replacing it.

Industry 4.0 and the Future of Smart Automation

Current automation trends point toward increasingly connected, intelligent, and autonomous manufacturing:

AI-Driven Predictive Quality: Machine learning models analyze process parameters, environmental conditions, and material characteristics to predict quality outcomes before production. Systems identify potential defects and recommend process adjustments proactively rather than detecting problems after occurrence.

Autonomous Production Planning: Advanced scheduling algorithms consider equipment capabilities, material availability, tool requirements, and customer priorities to optimize production sequences automatically. Systems dynamically rebalance workload across machines, accommodate rush orders, and minimize changeover frequency.

Collaborative Robotics (Cobots): Next-generation collaborative robots work safely alongside human operators without safety caging. Cobots handle repetitive positioning, material handling, and measurement tasks while humans provide judgment, problem-solving, and quality verification.

Edge Computing and Real-Time Analytics: Processing data at the equipment level enables immediate response to changing conditions without network latency. Real-time analytics support split-second process adjustments that optimize quality and efficiency continuously.

Digital Thread and Supply Chain Integration: Connected manufacturing systems share data across the supply chain, from customer order through design, production, quality verification, and delivery. Digital thread technology ensures design intent, manufacturing parameters, and quality documentation flow seamlessly across all parties.

Practical Limitations and Implications for Your Projects

Practical Limitations and Implications for Your Projects

When evaluating metal fabricators for your project, understanding their automation capabilities reveals capacity for consistent quality and delivery:

Quality Consistency: Fabricators with smart automation typically demonstrate tighter tolerances, more consistent finishes, and lower defect rates. Automated processes reduce variation inherent in manual operations.

Capacity and Scalability: Automated facilities can absorb volume increases, accommodate rush orders, and maintain delivery schedules more reliably. Smart automation provides capacity flexibility without proportional workforce expansion.

Engineering Support: Manufacturers investing in automation typically maintain strong engineering capabilities. Automation requires deep process understanding, systematic problem-solving, and continuous improvement—capabilities that benefit custom project execution.

Lead Time Predictability: Automated production scheduling and real-time monitoring improve delivery date accuracy. Fabricators can provide reliable timelines and accommodate just-in-time delivery requirements.

Process Documentation and Traceability: Smart automation systems inherently capture production data, quality metrics, and process parameters. This documentation supports quality verification, compliance requirements, and continuous improvement initiatives.

Frequently Asked Questions

Does automation mean fewer skilled workers in metal fabrication?

No. Smart automation changes roles rather than eliminating workers. Automated fabrication facilities need more programmers, technicians, process engineers, and quality specialists. Automation expands capacity, allowing companies to grow without reducing skilled labor.

How long does smart automation implementation take?

Implementation varies by scope. A single robotic cell often takes 3–6 months from purchase to production. Multi-step automation programs involving bending, cutting, welding, and powder coating typically require 12–24 months. Phased adoption shortens ROI timelines and reduces risk.

What production volumes justify automation investment?

Smart automation can justify ROI at lower volumes than traditional automation, often at 10,000–50,000 parts annually depending on part complexity. For high-mix, low-volume shops, gains come from reduced setup time, consistent quality, and improved throughput rather than pure volume.

Can automation handle custom or one-off sheet metal parts?

Yes. Smart automation excels at variable, complex, or custom part production thanks to adaptive controls, fast programming, and quick changeover capabilities. Automation delivers consistent quality even on highly variable or prototype-driven jobs.

How does automation affect manufacturing lead times?

Automation typically reduces lead times by 20–40% through faster cycle times, repeatable processes, reduced scrap, shorter changeovers, and unmanned shift operation. Real-time monitoring also improves scheduling accuracy and delivery reliability.

What is the difference between smart automation and traditional automation?

Traditional automation performs fixed, repetitive tasks with little flexibility. Smart automation uses sensors, AI, machine learning, and adaptive control to respond to variation, optimize performance, and maintain quality automatically. It is ideal for complex, high-mix fabrication environments.

What technologies enable smart automation in sheet metal fabrication?

Smart automation relies on robotics with vision and force sensing, AI-driven process optimization, digital twins, IoT-enabled predictive maintenance, real-time production monitoring, and adaptive CNC systems. Together, these tools improve quality, throughput, and consistency.

Is smart automation expensive to maintain?

Maintenance costs depend on system complexity but are often lower than manual processes due to predictive maintenance, fewer equipment failures, and reduced scrap. Automated systems typically have clear service schedules and remote monitoring to prevent breakdowns.

How does automation improve quality in metal fabrication?

Smart automation improves quality through adaptive process control, consistent force application, real-time measurement, vision-based inspection, and automated parameter adjustment. This reduces variation, increases first-pass yield, and improves overall part consistency.

Why should customers care whether a fabricator uses smart automation?

Fabricators using smart automation typically deliver more consistent quality, faster lead times, better repeatability, and improved scalability. Automation also enhances documentation, traceability, and process control—critical for industries like medical, aerospace, and industrial equipment manufacturing.

Strategic Applications in Sheet Metal Fabrication

Strategic Applications in Sheet Metal Fabrication Practical Limitations and Implications for Your Projects

Practical Limitations and Implications for Your Projects