Updated: June 9th, 2022

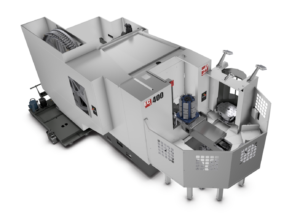

In 2020, our Austin, Texas CNC machine shop completed the installation of one of the most high-tech machines in which EVS has ever invested: a Haas EC-400. But getting the new machining center up and running was only the first step in what has been an incredibly educational few months, because the new EC-400 ultimately required we all start looking at CNC machining a little differently going forward, changing our perspective — literally! — on machining processes. Why this change? Because instead of the vertical orientation typical of so many CNC machining centers, the EC-400 is, instead, horizontal.

CNC Machining Goes Sideways

The Hass CNC mill is not only the first horizontal machining center for EVS Metal’s Texas machine shop, but it’s also the very first one of its kind that EVS has purchased for any of its four metal fabrication locations. This upgrades our Texas facility’s CNC machining capabilities enormously and demonstrates the company’s dedication to making capital investments across all of its locations.

So what makes the Haas EC-400 such an incredible CNC machine? Honestly, the list is long, but some of the features our team has found the most beneficial to our machining operations include:

- Ultra-high-speed 15,000 RPM spindle with high-pressure, through-spindle coolant

- 100+1 tool side-mount tool changer

- Six-station pallet pool, allowing our machinists to schedule and operate truly non-stop, lights-out parts processing

More “Fun Facts” About the EC-400 Horizontal Machining Center

As mentioned above, our new CNC machining center has some fantastic features, and those ultimately result in numbers like the below:

- The X, Y, and Z-axis rapid traverse is an incredible 1400 IPM

- The maximum true feed rate comes in at 833 IPM

- The rotational index rate at 90 degrees is 3 seconds

- Our axis travel for this machine is 22” (X-axis) x 25” (Y-axis) x 22” (Z-axis)

- The tool change on this is an amazing 2.8 seconds tool to tool, and 3.6 seconds with a maximum tool weight of 12 lbs.

What Does EVS Texas’ CNC Machining Investment Mean for Our Metal Fabrication Customers?

There are a huge number of advantages to customers who choose EVS Metal for their CNC machining needs. Faster, more automated processing with high levels of precision allows us to stay ahead of the curve and at the top of the market with shorter lead times and excellent part quality. And not just for the high volume production at which this machine excels, but for the high-mix/low volume runs the EC-400 does as well if not better than most other mills, and which so many of our customers require. While we have always been proud of maintaining a world-class machining operation at our Texas facility, the EC-400 has taken us to an entirely different level, one which has given us a whole new (horizontal!) perspective on CNC machining.