Wondering what metal fabrication is, or how to define it? Or, maybe you’re looking for more information about the types of equipment used in metal fabrication, or what types of metals can be fabricated. Well, you’re in the right place. EVS Metal has some of the most knowledgeable metal fab specialists in the world within their four American facilities, and they are always happy to share their expertise. Keep reading to learn more!

What is the Definition of Metal Fabrication?

Metal fabrication is defined as the process of producing precise shapes from sheet metal including steel, aluminum, and stainless steel. These shapes are created via a range of subtractive metal fabrication processes that require removing material (metal) from the raw metal sheet (also called a “workpiece”) in order to produce the desired shape. There are also non-subtractive metal fabrication processes that do not remove material, and instead, alter it via pressure or heat.

Most fabricated sheet metal pieces go on to be finished to varying degrees, using finishing processes like powder coating or direct-to-substrate printing. They are often assembled into larger metal parts or products, sometimes called weldments or assemblies, and may also require additional processes such as electromechanical integration for the product to be considered complete.

What are Common Metal Fabrication Processes?

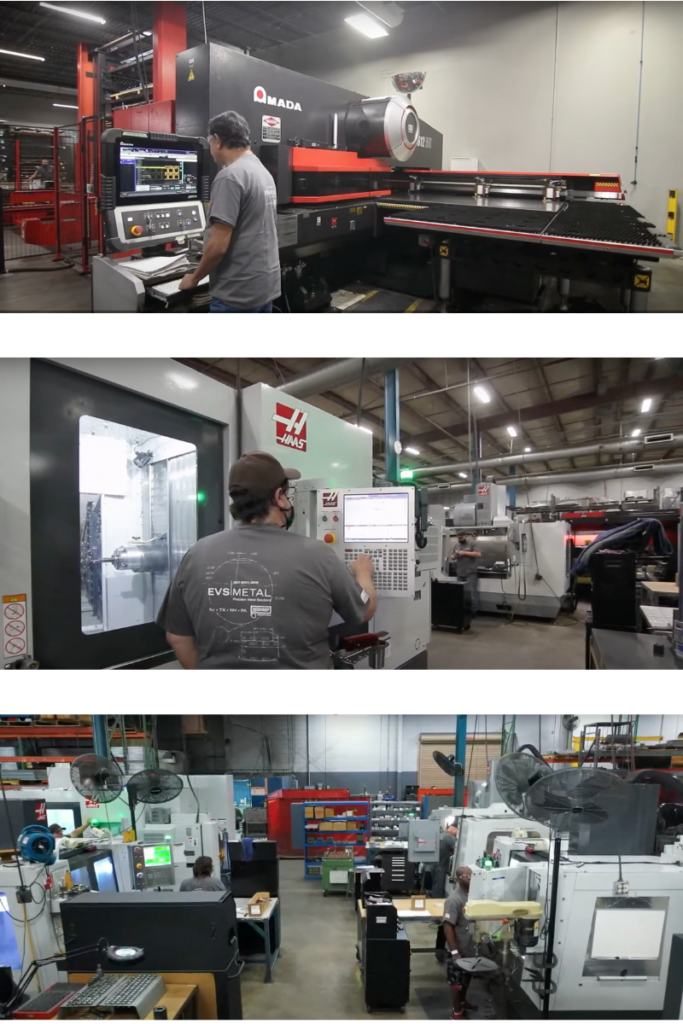

Metal fabrication includes a number of primary processes that create the initial shape required by the design and engineering plans. Most metal fabrication shops utilize automated computer-numerical controlled (CNC) technology to carry them out. Cutting and machining are the largest categories, but under them, there are a number of specific operations that can be carried out.

CNC Machining Cutting Processes (Metal “Chipping”)

- Milling: Utilizes rotary cutters to remove metal from a stationary workpiece.

- Drilling: Utilizes a rotating cutting tool to create round holes in a stationary workpiece.

- Turning: Unlike milling and drilling, turning requires that the workpiece is rotated rather than remaining still. The selected machining tool is programmed to move to and from the piece in order to remove material.

- Grinding: Removes small amounts of metal from the stationery workpiece via the use of a high-speed, abrasive wheel.

CNC machining can be carried out out at a machining company or within a turn-key metal fabrication facility with its own in-house CNC machine shop, like EVS Metal.

CNC Cutting Processes

Also known as “die cutting”; these processes do not create “chips” of metal, and instead, produce precise, clean cuts in workpieces.

- Punching: Consists of a large selection of tools, often called “rams,” that are used to create holes or other cleanly-edged shapes in sheet metal via a quick punching movement.

- Stamping: Depending on the type of tool used to create the “stamp” design, this process could be either subtractive or neutral, like bending. If metal is cleanly removed, then it would be considered a shearing process. Otherwise, it may fall under the category of metal “forming.” Stamping can only be carried out on very thin metal sheets.

- Laser Cutting: CNC laser cutting utilizes the high heat produced by laser technology to make extremely quick, clean cuts in sheet metal. It is one of the best ways to cut thick metal materials efficiently.

- Plasma Cutting: Utilizes an accelerated jet of hot plasma to make clean cuts in sheet metal.

Other Metal Fabrication Processes

There are many other operations offered by precision sheet metal fabrication shops beyond traditional subtractive metal fab processes. This is one of the benefits of utilizing a full-service contract metal fabricator like EVS; they are able to supply everything needed to complete a job in the same place, creating efficiencies that result in better quality as well as cost savings to customers.

These sheet metal manufacturing services include:

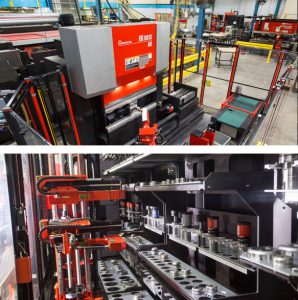

- CNC Forming

Metal forming includes processes like robotic CNC bending. Forming is used to reshape or “deform” sheet metal or metal tubing via the use of thousands of pounds of pressure applied by a press brake. This pressure changes the shape of the metal without removing material from the workpiece.

- Welding

There are two types of robotic and manual welding that are common in metal fabrication shops:- TIG welding: TIG stands for “tungsten inert gas,” and is also referred to as GTAW or ”gas tungsten arc welding.”

- MIG welding: MIG stands for “metal inert gas,” also known as GMAW or “gas metal arc welding.”

The primary difference between TIG & MIG welding is that MIG utilizes a continuously feeding wire, while TIG requires the use of long welding rods that are slowly fed into the weld puddle.

- TIG welding: TIG stands for “tungsten inert gas,” and is also referred to as GTAW or ”gas tungsten arc welding.”

Value-Added Services in Metal Fabrication

- Finishing: Metal finishing techniques are generally completed before assembly (there are exceptions), but after fabrication. These processes are used for many purposes, including to protect the surface of the product or part from wear or the elements (powder coating) or as a decorative or cosmetic option (#8 mirror finishing & polishing; silk screening).

- Assembly & Hardware Insertion: Often, a product may have a number of fabricated metal parts that need to be joined together to create the final product using fasteners, such as screws or bolts. For this reason, full-service metal fabricators offer on-premise assembly and hardware insertion services to help streamline production and speed to market.

- Integration: Products that contain electronic components, such as fans or chips, generally require that they be added before they can be used. Electromechanical integration is another service end-to-end fabrication shops like EVS Metal offer.

- Inventory, Shipping & Logistics Management: Full-service sheet metal fabricators like EVS offer customers options for handling everything from product warehousing to international shipping, including regional delivery by company-owned trucks.

Evaluating contract metal fabricators and CNC machining shops for your company’s manufacturing project? With nearly three decades of experience serving customers across the U.S. from locations in Texas, New Jersey, Pennsylvania and New Hampshire, EVS Metal has the expertise and dedication to customer service your business deserves.

Ready to learn more? Request a quote online or give us a call at 1-888-9EVSMET.