EVS Metal is very pleased to have been chosen as a “featured supplier” by the Design 2 Part Show team. Check out the video below, featuring Brent from our New Jersey precision sheet metal fabrication facility, or read the transcript to find out what he had to say about EVS Metal’s manufacturing capabilities.

[Intro]

“We are problem solvers, and everyone [customers] has a problem they have to deal with.”

“EVS manufactures everything from bare sheet metal to finished product with powder coating. We have lights out punching which runs 24 hours a day 7 days a week, [including] robotically loaded turrets [and] robotic brakes.”

[Shot Changes — Graphics]

Precision Metal Solutions: EVS Metal

Design 2 Part Featured Supplier

[Shot Changes]

“Hi, I’m Brent with EVS Metal. We specialize in precision metal solutions — sheet metal fabrication, precision CNC machining, in-house powder coating, value-added assembly and testing. We do everything from design support during R&D, up to final product assembly tests, kan-ban, delivery via our own trucks, and we can support you from start to finish.

[Shot Changes]

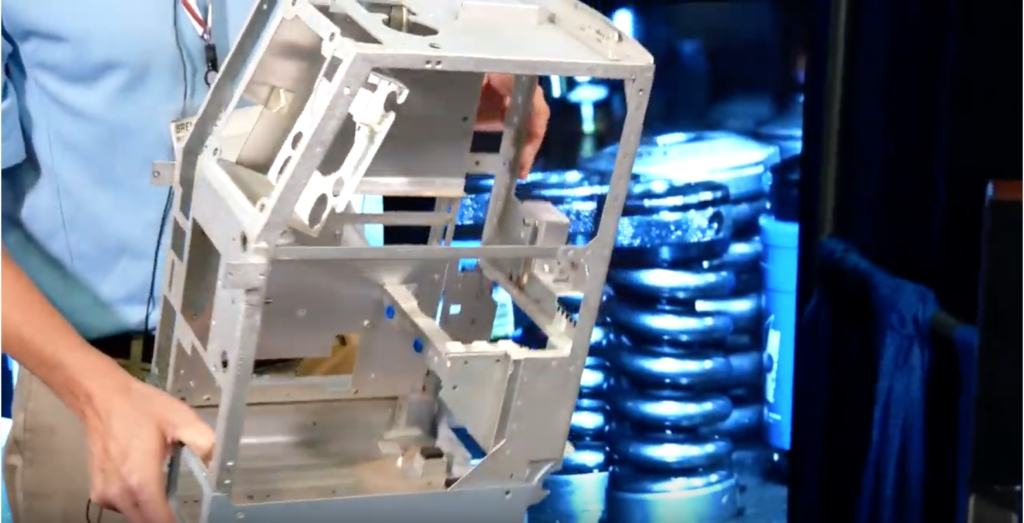

“Our parts are anything from small parts like the one I’m holding here — to [something like] a medical device (pictured above). [This is] actually a cart that wheels through a hospital, it’s a cardiac assist unit. It’s a very complex metal assembly; these are mounting ears for a handle, this is a welded component, there’s spot welding, there’s welding in the corner — it’s very thin-gauge aluminum, which is challenging to weld without distortion. The tolerance expectations are very high; we worked very closely with the customer on a means of meeting their cost expectations. it’s ultimately masked and powder-coated [and we manufacture] 1500-2000 a year, in a dedicated assembly cell.”

[Shot Changes]

“Everything is made in America. We have four sheet metal fabrication facilities servicing the whole country. We are in Riverdale, NJ; Keene, NH; Stroudsburg, PA; and Austin (Pflugerville), TX. 250,000 square feet [of space with] 250 employees; lights-out manufacturing (a lot of automation); robotic brakes [and] robotic welding.”

[Shot Changes]

“Customers come to us sometimes with prints only, sometimes with CAD data, or just a sketch, and they’re looking for help with the design — design for manufacturability. We specialize in that, [and] we can really help customers when we get involved early in the process to keep [unnecessary] costs out of the product, so when it comes to production, it’s not set up in a way that you’re married to something with too much welding, too much grinding.”

“One of our big successes was a customer who developed four different cabinets that were all welded and ground with hundreds of inches of precision welding. They needed a cost reduction, [and] their current supplier couldn’t help them. We were able to take 20% out of the cost of the product, and we ended up winning a million dollars worth of business.”

[Shot Changes]

“So this is a product we built for a customer up in New Hampshire, it’s actually ultimately a powder-coated product [and] this was a machined part originally. We bought a multi-access laser machine to be able to feed the tube into the machine and laser cut all the holes and all the features on this part and eliminate 40% of the cost.”

[Shot Changes]

“This is a relatively simple sheet metal enclosure, with some pem nut installation, some masking for grounding, and powder coating. There were some unique challenges with special radius tooling that we had to deal with. It’s also silkscreened — we do that in-house as well — and we did 3000 of these in a 2-month window, using robotic forming and lights-out punching.”

[Shot Changes]

“Customer service is the most important thing, so we work very closely with the customer to help them manage their challenges, and we have a lot of unique ways of doing that. We have customers whose demand can quadruple in one month with no notice, and we’ll source that product [internally]. We’ll share the files with our sister facilities to be able to handle that when it happens because we know it can happen and we communicate [that] upfront.”