EVS Metal has once again teamed up with Columbia University students to assist in fabricating precision metal parts for their student race car club — officially known as Knickerbocker Motorsports (Columbia FSAE).

Columbia FSAE is a student club that builds open-wheeled, formula-style race cars from scratch. Once completed, they travel to competitions to face other colleges and universities from around the world. In a twist, this year the team decided to manufacture two cars — a traditional gas-powered vehicle (ICE), and an electric vehicle (EV).

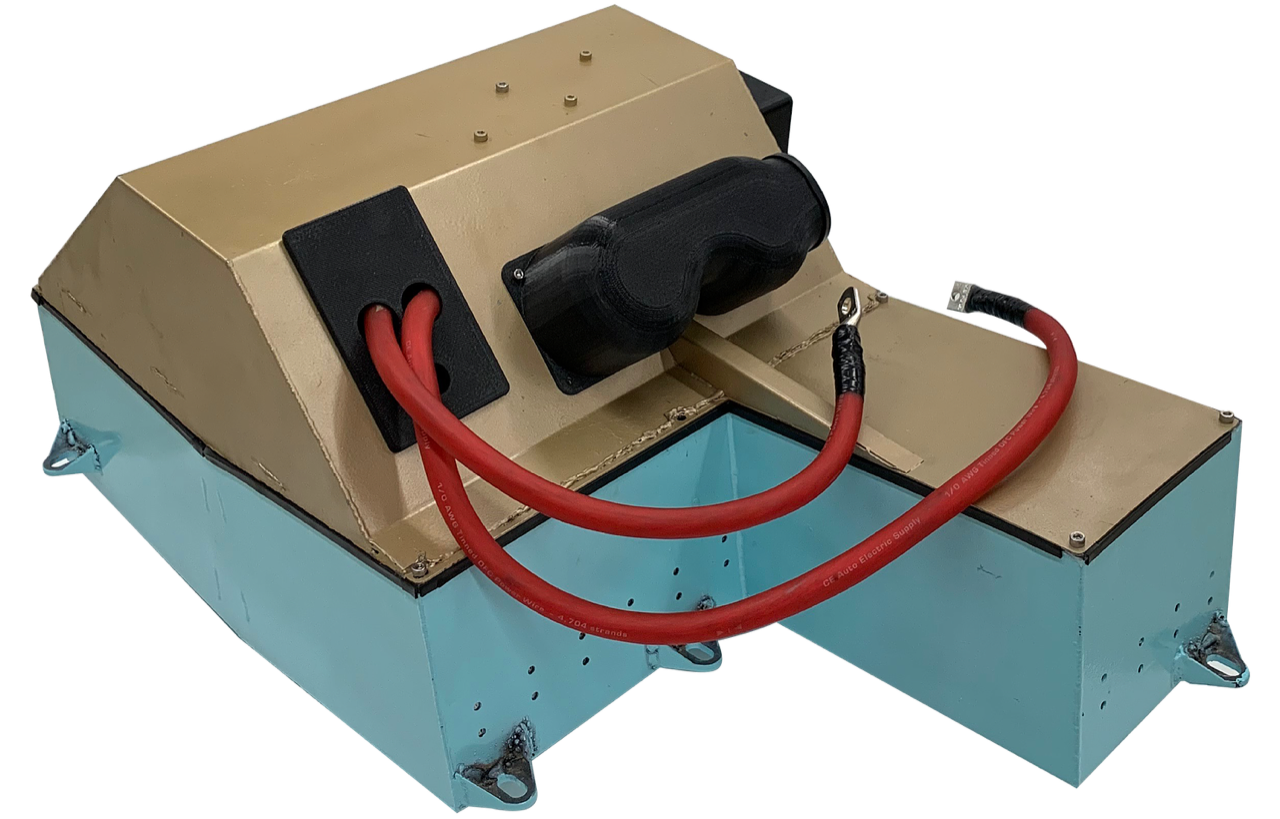

This year, EVS fabricated three different parts for Columbia; a fuel tank and tabs for the ICE, and an accumulator for the EV. “EVS helps us bring our designs to life through manufacturing,” said James Van Hess, Lead System Engineer for the club.

Last week, we talked about the ICE vehicle. This week, we are sharing details about their EV, the first time they’ve entered a car into the electric competition.

Columbia University FSAE’s First Electric Vehicle Comes to Life with a Little Help from EVS

EVS built an accumulator and accumulator “wing” for Knickerbocker’s electric vehicle, which they had intended to race at EV North, one of the major racing competitions. An accumulator is an important part, as it’s the container that serves as a house for five different lithium-ion battery segments and the high low voltage systems. It serves as a life support system for the batteries, insulating and protecting them, managing their output through the Battery Management System (BMS), and cooling them and their associated systems with three 130 CFM fans that induce airflow.

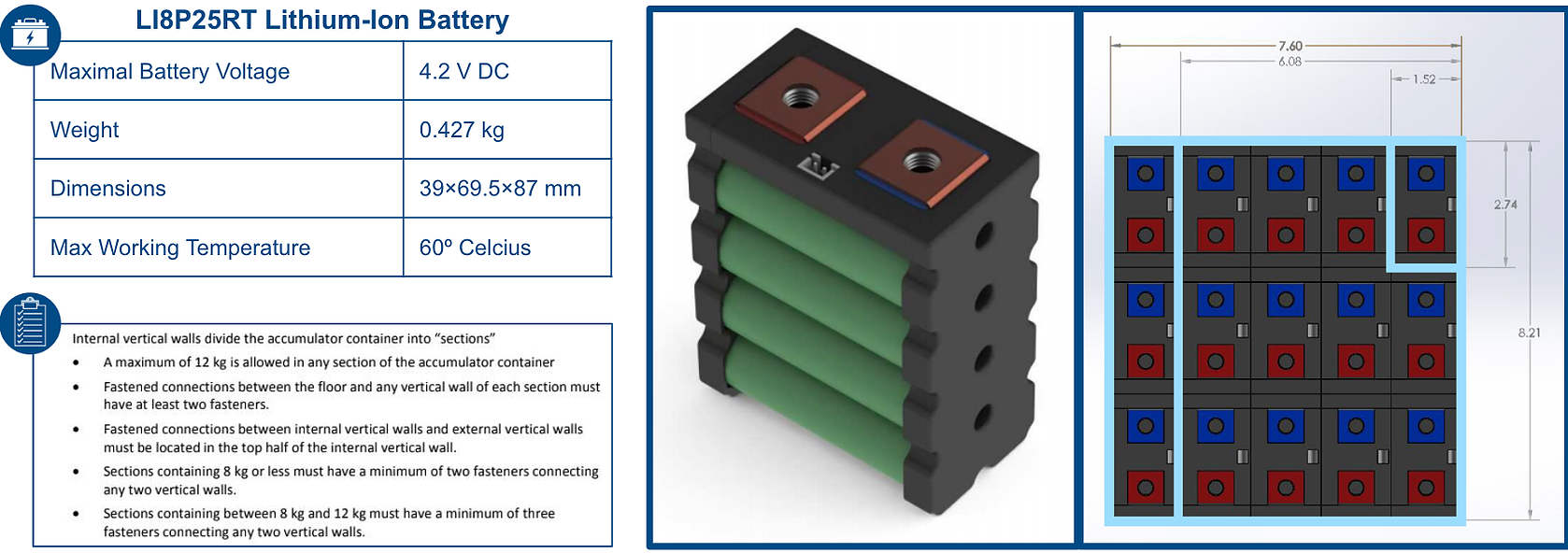

The car’s batteries are arranged asymmetrically in the accumulator; it includes four segments with 15 batteries, and one with 12, for a total of 72 overall. The asymmetric arrangement was implemented to maintain a low center of gravity within the narrow chassis, while allowing for the motor and differential to maintain the same powertrain plane used for the internal combustion engine.

Knickerbocker Race Team Gives EVS Metal’s Staff Big Kudos

According to the team, “EVS was able to laser cut and weld the parts in blazing time as we were under immense time constraints this year.” And, although the car was “ready” for EV North, it was decided that they didn’t have enough testing data to bring the car to the competition. Instead, three of the EV team members (who are also on the executive board for 2019-20) traveled to the race to gauge the performance level of the other vehicles. This ended up being a huge help to the team overall, as they returned with a considerable amount of valuable information that they plan on integrating into the EV in 2020, which they have every intention of entering in next year’s race.

Check out the image gallery below to see Knickerbocker’s EV and the parts EVS fabricated. We are excited to see how the team grows in 2020!

About EVS Metal

EVS Metal is an American precision sheet metal fabricator headquartered in Riverdale, NJ. Our machinists and operators utilize the latest technology to cut, bend and finish stand-alone items as well as parts for integration or assembly into more complex products. EVS Metal’s four ISO 9001:2015-certified locations comprise over 250,000 square feet of vertically-integrated manufacturing space and feature the most modern equipment available, from lasers and CNC machining centers to automated powder coating lines.

We serve a diverse customer base across North America, providing a range of services from quick-turn prototypes to high-volume production runs. Request a personalized metal fabrication quote online or call 1-888-9EVSMET to speak with a specialist today.