Quick Summary

American fabricator EVS Metal was approached by Whitestone Audio Instruments to fabricate crucial components for a new audio engineering product after experiencing multiple issues with both U.S.-based and overseas manufacturers.

About Whitestone Audio

Whitestone Audio Instruments is the result of a 5-year research and development journey undertaken by husband-and-wife team Dave and Kim Rosen to create a unique analog processing device for professional audio engineers. Kim is a well-known, Grammy®-nominated audio mastering engineer while Dave and his Karcorp Visual Media Specialists have spent the better part of the last two decades helping companies inside and outside the pro audio business launch successful products.

About EVS Metal

EVS Metal is a leading American metal fabricator with more than a quarter-century of experience delivering sheet metal prototypes and full production product runs in concert with industry-leading quality and customer service. EVS provides precision aluminum and steel sheet metal fabrication, CNC machining, mechanical assemblies and integration services to commercial customers across North America from metal fabrication facilities in NJ, TX, NH & PA.

Project Overview

EVS Metal was approached by Whitestone Audio Instruments to fabricate crucial components for its new, cutting-edge music production device, the P331 Tube Loading Amplifier. Whitestone had encountered a number of supply chain issues with both American companies and those overseas while trying to bring their product to market. EVS enabled Whitestone to make their project come to life, with greater transparency and convenience than they had been able to find overseas, and with better customer service and attention to detail than any other American metal fabrication company had offered.

The Product

The P331 Tube Loading Amplifier, which features a Class A fully-differential analog tube amplifier designed around 6SN7 dual triode vacuum tubes. This tube was introduced in 1939 and while the 6SN7 is somewhat rare in pro audio applications, it is relied upon in the hi-fi market for its inherent “clean and silky” characteristics in audiophile preamps. It is essentially a vacuum tube amplifier with a host of controls that can alter the way the tubes and other internal analog circuits affect the sound of the audio passing through, adding enhanced size and depth to recorded music.

The amplifier was originally developed as a custom piece for Kim’s New Jersey-based audio mastering studio, Knack Mastering. “Audio mastering is the final step in the production of a musical artist’s recording.” explains Kim. “It’s the last opportunity for a trained and experienced engineer to listen to the final recording to ensure it sounds the best it possibly can and that all formats are prepared correctly for distribution out into the world.”

“For good reason, there is still demand for boutique analog audio equipment,” she continues. “There’s a ‘magic’ that can be achieved; with vacuum tube equipment most specifically. When I’m tasked with taking recordings of the highest caliber and squeezing one to two percent better sound out of them without harming their original intent, I won’t use digital to try and achieve the sound of analog. This is why we developed the P331.”

The Challenge

Whitestone Audio had the challenge of being a small company that also required customized components for a specialized product. This meant that many American manufacturers either turned them down immediately due to their lack of a track record, or sent quotes that were far higher than necessary in order to discourage Whitestone from moving forward with them.

“I could barely get anyone locally to give me the time of day when we were trying to launch this product,” says Dave. “We were just too small of a start-up (with no sales history) for anyone to care…and the quotes I received for metal were simply unrealistic. I felt like people didn’t really want the business because we were ‘small potatoes’ so they just sent outrageous quotes to make us go away. It was so discouraging.”

Dave then felt forced to seek out alternatives in Asia for the first production run. “Of course, working with a company on the other side of the planet introduces a different set of challenges, and it’s precisely why I never wanted to have my metal produced in Asia,” Dave added. “The middle-of-the-night video chats with Asian factory reps, the logistics and red tape of shipping parts by sea, the freight forwarders, customs, and of course, approving of final production parts from mediocre cell phone photos — It all seemed so unnecessary to me when I had local metal shops I could be working with.”

The Solution

When it came time for the second production run, Dave did some research on local companies, and reached out to EVS Metal to set up a meeting, where he first connected with Brent Frey, EVS’s business development manager.

“I was able to explain, in person, how challenging it was finding a local, high-quality metal shop that would be willing to work with a smaller but growing customer,” Dave says. “I explained how insane it was for me to be producing metal parts on the other side of the earth when EVS’s New Jersey facility is 12 minutes away from me.”

Brent agrees. “Whitestone is a local company, and we felt there was a significant opportunity to develop a strong relationship, starting with this project, that could grow over time. The fact that Dave is local made it especially interesting. COVID has generally made in-person meetings difficult or impossible, but in this case, because he was so close, safe, in-person meetings could be had as there was no need for anyone to travel long distances on public transportation to make them happen. This meant Dave could bring in samples that we could look at as a team, which helped communication and progress significantly. He was really excited about our state-of-the-art equipment and how it would be used to produce his parts, and thrilled it was all being done locally.”

“And I was clear that I had no illusions I’d be able to get the kind of pricing I’d get staying in Asia,” adds Dave. “But I was willing to pay more to reduce the hassle and improve the process. Basically, I was willing to give a little on price to keep things local and I needed a partner who would be willing to do the same. Thankfully, EVS Metal turned out to be that partner.”

The Plan

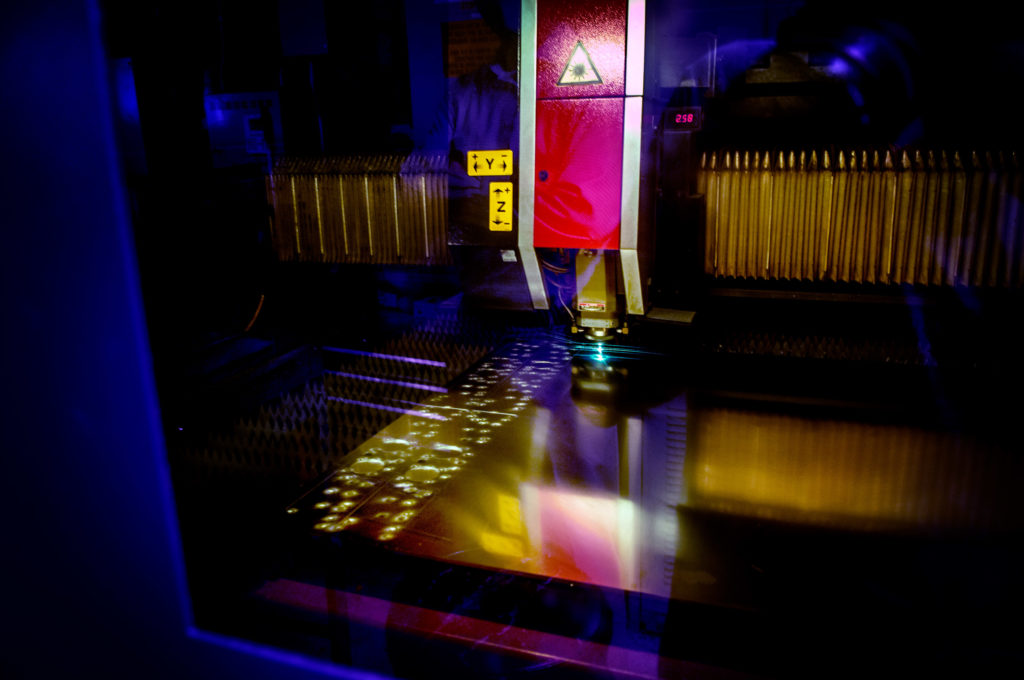

Brent brought in EVS’s New Jersey engineering manager, Nathan Lee, and the two began working closely with Dave to understand what was needed for his project at a cost that worked for both parties. A plan was then formulated that called for laser-cut aluminum front panels, bent sheet metal enclosures, and punched top panel vent holes.

“The original plan was to fabricate the 16 gauge CRS main enclosure with a turret-laser combo, but since Dave was interested in the fabrication process, and, understandably, keen on keeping costs down, we were able to have an ongoing conversation throughout production,” says Nathan. “This frequent communication eventually allowed us to find ways to use punch tools from our existing inventory to provide the cutouts he needed while avoiding custom tools and punching fully on the turret.” After punching was completed, it was then formed on the press brake, and PEM hardware was installed. But the biggest challenge was yet to come.

“The front panel called for ¼” aluminum. This was the most difficult part since it is the most visible piece on the unit and has hole diameters that are less than half the thickness,” says Nathan. “With these holes being used for pressure fit light pipes calling for 0.114 dia +.003/-.000, they needed to be cut perfectly. And again, because Dave is local, we were able to run some test panels with him literally right there, ready with the parts that go into the holes so we could be absolutely positive about the fit. This meant we could keep these ‘test’ panels as part of the production run, and it absolutely helped keep costs down.”

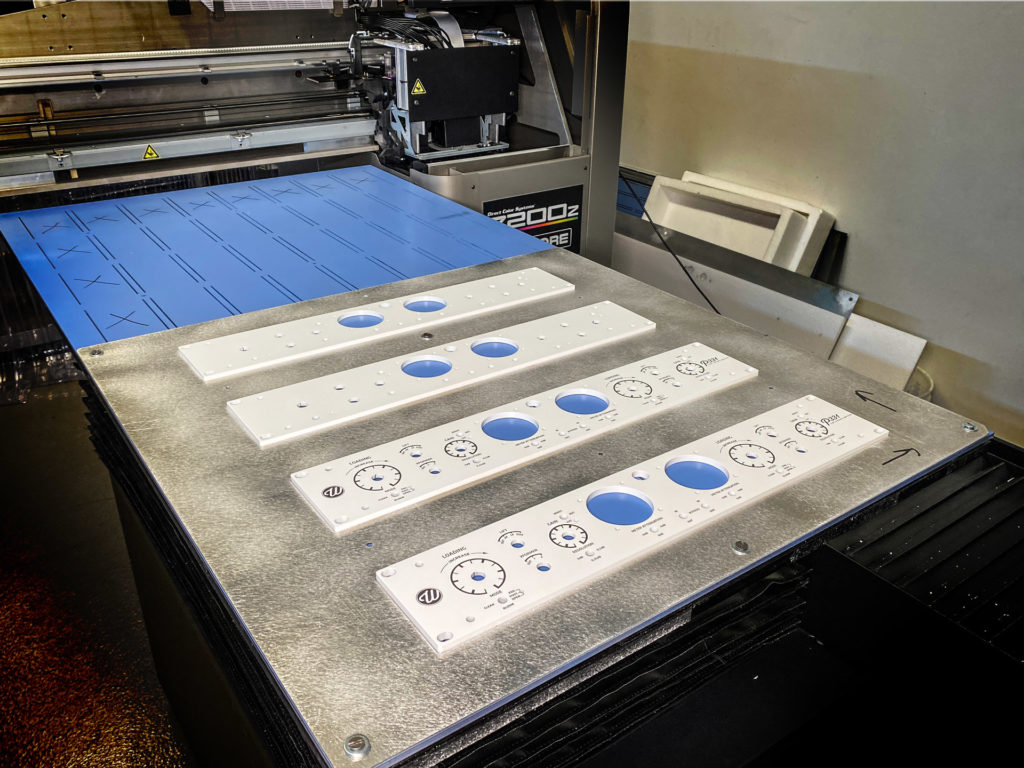

From there, it was off to the finishing department, where all parts were powder coated, and the enclosure was silk-screened. Whitestone also opted for direct-to-substrate UV-printed front panels. “We were able to achieve the high cosmetic expectations on the P331’s finish and artwork, like the front panels, almost entirely due to our latest machine acquisition — a direct to substrate Direct Color Systems inkjet printer. Independent testing has proven it to outperform silk screening in durability and quality. This ensured that even the smallest text was crisp, clean and easy to read.”

“Our direct to substrate [DTS] printer utilizes a direct jet UV, and for the record, it is a very, very large printer, not something portable like what you might use with a laptop computer,” adds Nathan. “It has a stationary table where the parts that will be printed on sit. The print head then passes over the parts in a back-and-forth motion, traveling the length of the bed in order to print the required artwork. There is a UV light on both sides of the print head; when the trailing light turns on, it cures the ink instantly. This allows us to immediately pack parts right off the machine, which is a big benefit over traditional silkscreening, which requires time to dry.

“We made the decision to use the DTS printer after talking to Dave about the look he wanted for the printed lettering on the front of the enclosure,” Nathan continues. “He had shown us the powder and silkscreen color on the samples from Asia, which were close to what we wanted, but not exact. One way in which the DTS printer excels is that it is able to create extremely precise color matches by using a combination of CMYK, white, black, and clear liquid inks to produce process colors. This means we are able to print any color, and make subtle adjustments in order to get exactly the right shade. When we had the painted front panels, we were able to adjust the color on the printer to give him exactly the shade of grey that he wanted, but was unable to achieve on his samples from overseas.”

The Result

Overall fit and finish of the components were better and more consistent once Whitestone partnered with EVS. The availability of UV printing at EVS’s New Jersey facility allowed for accuracy that is difficult to achieve with silk screen printing, and the powder coat application was infinitely more consistent than what had been provided previously by overseas manufacturers. The result was a product that looked and functioned exactly as Whitestone had intended.

The Conclusion

“The entire experience was just as we’d hoped,” says Dave. “Less hassle, lower stress, great quality. And best of all, I get to go to sleep at night knowing I’m doing business with a local company that employs people in my community. We can all use a reminder at times that we’re in this together and it’s up to us to make the change we’d like to see. We are looking forward to working with EVS Metal on many more projects in the future!”

Says Brent, “It was a pleasure working with Dave on this project. He is as passionate about his products as he is about manufacturing them in the United States. This is a refreshing viewpoint and we were happy to help him achieve his goals. We look forward to a continued and expanded relationship with Whitestone Audio.”

“Our business is about relationships and a commitment to our customers,” he continues. “We feel if we can help them solve their challenges and achieve their goals, our own successes as a sheet metal solutions provider will naturally follow.”