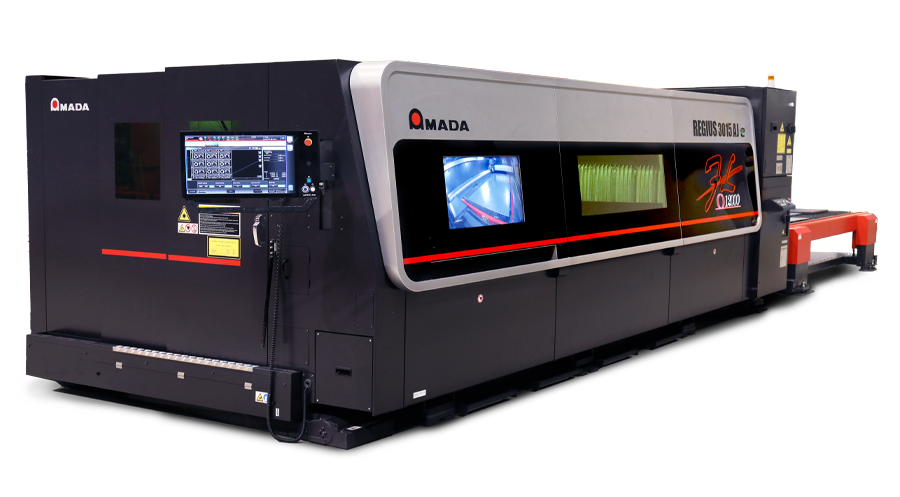

At EVS Metal, we’re constantly striving to provide our clients with the highest quality, fastest turnaround times, and most cost-effective metal fabrication solutions. That’s why we’re thrilled to announce a major upgrade to our Riverdale, New Jersey facility this March: the addition of a brand-new Amada REGIUS 3015 AJ 6kW fiber laser cutting system! This cutting-edge technology represents a significant investment in our capabilities, and it translates directly into benefits for you, our valued customers.

The Amada REGIUS 3015 AJ isn’t just any laser cutter; it’s a top-of-the-line fiber laser system designed for maximum speed, precision, and efficiency. The “6kW” refers to its 6-kilowatt laser power source – a significant step up from many older laser systems. This means:

- Faster Cutting Speeds: The 6kW laser can cut through various metals, including steel, stainless steel, aluminum, and even copper and brass, significantly faster than lower-powered lasers. This means quicker turnaround times for your projects.

- Unmatched Precision: The REGIUS boasts incredibly precise cutting capabilities, allowing for intricate designs and tight tolerances. This is crucial for projects that demand the highest levels of accuracy.

- Superior Edge Quality: Fiber lasers produce a cleaner, smoother edge compared to traditional CO2 lasers, often eliminating the need for secondary finishing operations. This saves time and reduces costs.

- Thicker Material Cutting: The 6kW power allows us to cut through thicker materials than before, expanding the range of projects we can handle. Specifically, up to 1″ steel, 1″ stainless steel, and 1″ in aluminum.

- Reduced Operating Costs: Fiber lasers are more energy-efficient than CO2 lasers, which helps us keep our prices competitive.

- Automatic Nozzle Changing: allows the laser to move seemlessly between materials and thicknesses, without stopping.

Key Features of the REGIUS 3015 AJ :

- Linear Drive System: The REGIUS uses a three-axis linear drive system, which provides faster acceleration and smoother motion compared to traditional rack-and-pinion systems. This contributes to both speed and accuracy.

- Amada’s Original Variable Beam Control Technology: This automatically adjusts the laser beam’s shape and diameter to optimize cutting for different materials and thicknesses.

- i-Process Monitoring: This advanced system monitors the cutting process in real-time, detecting any issues and automatically adjusting parameters to ensure consistent quality.

- Automatic Nozzle Changer: Speeds up setup times and reduces downtime.

- Large Work Area: A work area of 120.5″ x 61.2″.

Benefits for EVS Metal Customers

So, what does all this high-tech wizardry mean for you? Here’s the bottom line:

- Faster Turnaround Times: Get your projects completed quicker than ever before.

- Higher Quality Parts: Benefit from the superior precision and edge quality of fiber laser cutting.

- Greater Design Flexibility: We can handle more complex and intricate designs.

- Competitive Pricing: Our increased efficiency helps us keep our prices competitive.

- Wider Range of Materials and Thicknesses: We can handle a broader range of projects than ever.

EVS Metal’s Commitment to Excellence

This investment in the Amada REGIUS 6kW fiber laser is just the latest example of EVS Metal’s ongoing commitment to providing our customers with the best possible metal fabrication services. We continuously invest in the latest technology and training to ensure that we remain at the forefront of the industry. Our team of skilled fabricators and engineers is ready to put this new machine to work for you!

Ready to experience the difference that cutting-edge laser cutting technology can make? Contact EVS Metal today for a quote on your next project. In the meantime, check out the REGIUS in action!